Electrical calibration

Do you, like many other companies, depend on accurate and traceable electrical calibration of your measuring equipment? When maintenance is needed quickly, it’s helpful to have a specialist on hand. Minerva Metrology & Calibration helps calibration laboratories and departments with service/maintenance and recalibration of their own reference standards for over 30 years

So feel free to entrust your most accurate electrical calibration measuring instruments to us.

We work quickly, reliably, and transparently.

What is electrical calibration?

Electrical calibration is the critical process of verifying the accuracy of a electrical measuring instrument by comparing its readings to a known and trusted standard. This ensures that the measurements provided by the device are reliable and consistent, a cornerstone for safety, quality, and efficiency across a multitude of industries.

The fundamental principle of electrical calibration involves placing the instrument under test alongside a reference device of higher accuracy. Any discrepancies between the two readings are recorded, and adjustments can be made to the instrument being tested to bring its readings in line with the standard. This process helps to counteract the natural drift and wear that can cause instruments to lose their accuracy over time.

Why is Electrical Calibration so important?

Electrical calibration is critically important for several key reasons, especially in industries and applications where precision, safety, and compliance are non-negotiable. Here’s why it matters:

Accuracy and Reliability

- Over time, electrical measuring instruments (like multimeters, oscilloscopes, or sensors) can drift from their original specifications.

- Calibration ensures these instruments provide accurate and reliable readings, which is vital for any technical process.

Safety

- Inaccurate measurements can lead to dangerous conditions—especially in high-voltage systems or critical installations.

- Calibrated tools help prevent electrical failures, fire hazards, or equipment damage by ensuring correct readings.

Compliance with Standards

- Many industries (e.g., aerospace, automotive, healthcare, manufacturing) must follow strict standards like ISO, IEC, or NIST.

- Regular calibration is often a regulatory requirement for maintaining certifications and passing audits.

Cost Reduction

- Prevents costly errors, rework, or downtime caused by incorrect measurements.

- Helps optimize processes and reduce energy waste in electrical systems.

Consistency and Traceability

- Calibration provides traceability to national or international measurement standards, ensuring consistent results across different labs, factories, or teams.

Quality Assurance

- Ensures that products are built and tested with precision.

- In production, poor calibration can lead to defects or failures, hurting brand reputation and customer trust.

Electrical calibration ensures that instruments are accurate, safe, compliant, and cost-effective. Without it, you’re essentially guessing—putting quality, safety, and reliability at serious risk.

Why electrical calibrations at Minerva Calibrations?

We arrange the electricalmeasuring instrument calibration in our partner’s laboratories accredited according to ISO/IEC 17025 by their national accreditation body. This way, we can guarantee that your temperature calibration is traceable to SI.

We firmly believe that calibration service is and will always be a human endeavour. That’s why we ensure you always have a dedicated contact person and personalized service. This is especially helpful if your instrument needs urgent maintenance.

We’re amazed ourselves: our team now works for over 1,000 clients in 69 countries. Most have built long-term partnerships with us. Why? We believe in technology, innovation, and communication.

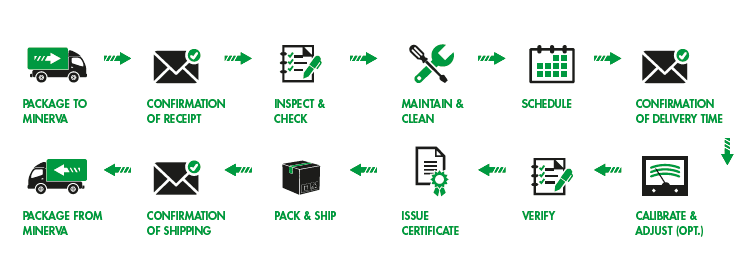

Sending your instrument for repair or calibration is never a convenient time. We understand that perfectly. Don’t worry. In the Minerva online portal, you can track the service progress, from day one through delivery.

Advantages of electrical calibration

- Accurate and reliable electrical measurement

- Optimal performance of your instrument or machine

- Prevents waste

- Process improvement and profit optimalisation

- Detection of obsolete equipment

Various brands

We arrange for you the maintenance, repair and calibration of a wide range of temperature measuring and calibration equipment from various brands.

Examples include: Fluke, Guildline, Wavetek, Datron , Keysight, Transmille, Hewlett-Packard, IET, Agilent, Keithley, Philips, Yokogawa, Rohde & Schwartz, HP, GE, Additel , Avantest , Ametek, Amprobe, Anritsu, Anton Paar, AIOP, Beamex, Beha- Amprobe, Bruel-Kjaer, Burster, BK- precision, Camille-Bauer, Chroma, Clark-Hess, Chauvin-Arnoux, Druck, Genrad, Genrad -IET, GW- Instek, Gossen-Metrawatt, Haag, Tinsley , HIOKI, HBM, Kistler , Klasmeier, Krohn-Hite, Labfacility , LeCroy, Leeds & Northrup, Meatest, Megger, Metrohm, Isotech, ITT, Precision Measurements, Pendulum, PCB Piezotronics , QuadTech, Testo, Thermo Electric, Time-Electronic, Thurlby, TTI, Tegam, Tektronix, Wayne Kerr, Yokogawa and Zera.

Electric calibration costs

Every request is unique. That’s why we determine the cost based on the type of measuring instrument, the maximum accuracy of the instrument, and the measuring procedure. This way, you never pay too much. Calibrating a electrical quantity measuring instruments naturally has a different cost than maintaining a large device.

For a quote with an exact price, please send an email to sales@minerva-calibration.com. Briefly describe your situation and needs. Or click the quote request button below.

Need electrical calibration?

Are you looking for a professional and reliable partner for your valuable instruments? Minerva Metrology & Calibration has been active in organizing the calibration of high-quality temperature and temperature calibration measuring instruments for over 30 years. So no device will hold any surprises.

Our team is highly trained, yet we are continuously working to improve the quality of the calibration process. This results in short lead times and high customer satisfaction.

Take advantage of our knowledge and experience and contact us for your challenge