Generating high accuracy negative gauge pressures with an absolute piston gauge with barometric reference, tends to be difficult and time consuming. Minerva has engineered a high-end platform for negative gauge pressure using an existing type of piston-cylinder with well-known temperature and pressure dependency. This system is much quicker, more user friendly and highly accurate.

- Perform negative gauge pressure calibration using your existing Fluke/DHI piston-cylinder module

- Compatible with PC-7100/7600 10 piston-cylinder modules

- Stable and robust construction

- Ergonomically design

- High accuracy

- User friendly

The MNR 700 piston gauge platform for negative pressure is based on the fundamental principle of mass loaded onto a piston to apply a know force to a know effective area. By using your existing high quality, high specification piston-cylinder from Fluke/DHI you extend you metrological capabilities. These standard Fluke/DHI piston-cylinders allow you to change the modules in just a few seconds without using tools.

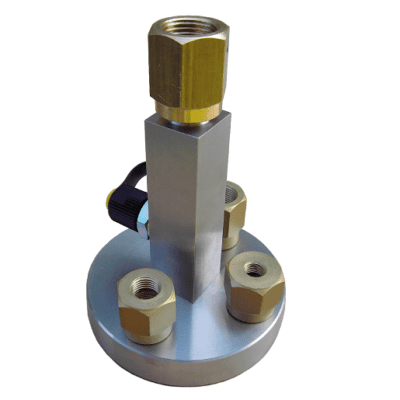

Piston Gauge platform

The platform is constructed using a triangular base plate with three solid stainless steel pillars. These pillars support the triangular top plate which holds the central metrological pilar, the heart of the system. The central pilar holds the masses and is the connection for the Fluke/DHI piston-cylinder modules. The pressure reference port is located on the back side of the platform.

Mass loading

Since the piston-cylinder is installed up side down which is reversed from it the normal mounting position in the Fluke/DHI PG platforms it is not possible to load the masses like a standard PG platform. Therefore the masses are already loaded on the central metrological pilar of the MNR platform before the piston-cylinder is installed.

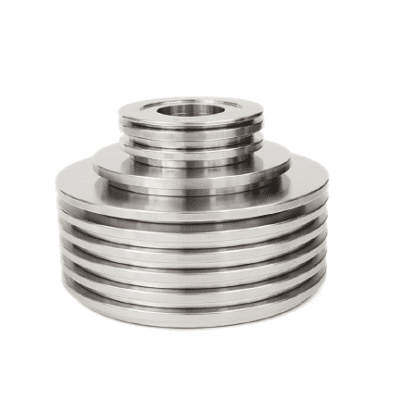

Integrated piston-cylinder metrological modules

Each PG7000 piston-cylinder is an integrated metrological assembly that includes the critical piston-cylinder mounting components. To change piston-cylinders, the complete module is installed and removed from the piston gauge mounting post. All of the mechanical parts that affect piston-cylinder metrology are associated with the individual piston-cylinder rather than being common parts of the piston gauge platform. This unique design provides many practical and metrological benefits.

Benefits

- Change piston-cylinder in seconds without using tools

- Handle and interchange piston-cylinders without exposing critical surfaces to contamination

- Protect the piston-cylinder from damage due to accidental shock or impact when handling

- Improve measurement reproducibility by avoiding frequent assembly/disassembly of mounting components and assuring that each piston-cylinder is always used with the same mounting hardware, even when used in a different platform

PG7000™ piston-cylinder modules

The piston-cylinder defines effective area and is the piston gauge’s principal metrological element. The piston-cylinder’s intrinsic characteristics and how it is mounted and exploited are the keys to piston gauge performance. PG7000 piston-cylinders are manufactured by Fluke/DHI using proprietary production techniques developed specifically for the PG7000 series.

These result in pistons and cylinders whose typical shape is within less than 0.2 micron from ideal geometry. Gas operated piston-cylinders use large diameters and very small annular gaps to minimize gas species and operating mode effects and to maximize piston float times. For example, the typical annular gap of a 35 mm gas operated piston-cylinder is less than 1 micron.

The pistons and cylinders are made of tungsten carbide. The piston-cylinder is a complete, integrated metrological assembly that includes the critical piston-cylinder mounting components. This approach improves metrological performance as well as offering many practical advantages. The piston-cylinders use free deformation mounting systems in which the cylinder is allowed to deform under the influence of applied pressure without O-rings or seals along the cylinder length.

Technical specifications MNR700-NGP

|

General specifications |

|

|

Power requirements |

80 V to 264 V ac, 20 VA max consumption |

| Operating temperature range | 15 °C to 25 °C |

|

Weight |

~ 30 kg |

|

Dimensions (H x W x D) |

370 mm x 425 mm x 500 mm |

| Communications ports | USB (simulated RS232) |

| Pressure connection | 1/8” NPT |

| Pressure ranges | -8..-98 kPa g |

| Operating media | Clean dry nitrogen |

| Mass carrying bell | ~ 300 gr |

| Main masses | 9 x 1 kg |

|

Fractional masses |

1x 500, 1x 250, 4x 50 gr |

| Ambient and instrument condition measurement | |

|

Piston-cylinder temperature |

Range: 15 °C to 25 °C |

|

Piston position |

Range: -4.5 … 4,5 mm Resolution: 0.1 mm |

| Piston rotation (rate and deceleration) | Range: 0 to 50 rpm Resolution: 1 rpm |

|

Ordering code |

MNR-700-NGP |

|

Piston-cylinder module specifications The PC 7100/7600-10 piston-cylinder is an integrated module which including mounting hardware delivered in |

|

| Cylinder material | Tungsten carbide |

| Piston material | Tungsten carbide |

| Mounting system | Negative free deformation |

| Pressure measurement Sensitivity |

0.02 Pa + 0.5 ppm |

| Reproducability | ± 2 ppm |

| Uncertainty | ± (0.2 Pa + 12 ppm) |

| Typical drop rate | 0.2 mm/min @ 350 kPa |

| Ordering code | PC-7100/7600-10-L |