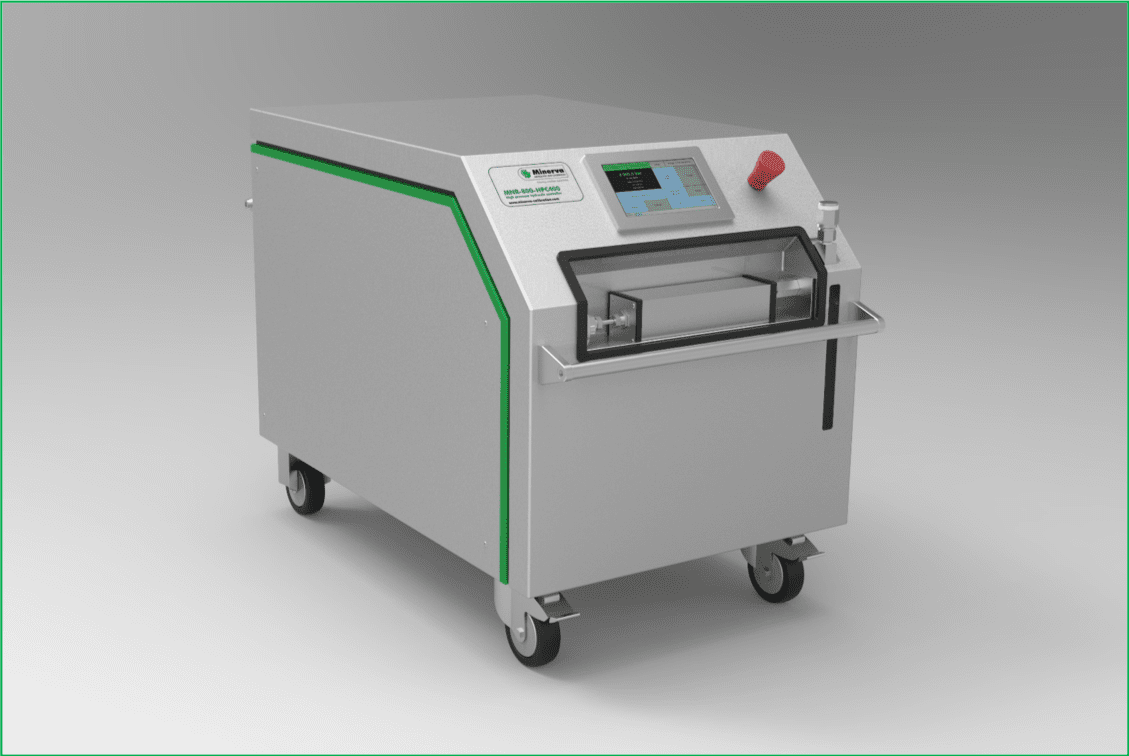

We proudly present to you the hydraulic high pressure controller MNR-800-HPC400!

This brand new Minerva product offers carefree hydraulic pressure calibration and testing up to 400 MPa (58,000 psi).

- Unique, patented high pressurecontrol technology

- High speed operation, typically pressure setting time less than one minute

- Very reliable in continuous operation, even in highest pressure ranges

- Tolerant of varying test volume

- High precision pressure control

- High accuracy quartz reference sensors with accredited calibration

- Local touch screen user interface and full remote control

- Simple and fast nudge/small step capability for analog gauge calibration

- Integrated test oil fill and gas purge system

Read more about the MNR-800-HPC400 at the special website page with extra material like a video, an extensive user manual and an article about remote communication.

Introduction

The HPC is intended to generate and control pressure as needed to calibrate and test pressure measuring instruments in wide variety of applications.

The HPC uses innovative pressure generation and control technology, developed and proven over several years in intensive operation with a major transducer manufacturer.

This versatile technology sets pressure very quickly and precisely into varying test volumes over a very wide pressure range. The very robust design provides exceptional reliability, allowing years of uninterrupted operation.

Applications

Pressure sensor manufacturing & testing

HPC can be used in the development, compensation and final calibration of various pressure measuring instruments. It sets pressure quickly and precisely even in large test manifolds and is engineered to support long and complex, fully automated test sequences. Most test manifolds can be filled and purged using HPC’s on-board capabilities.

Downhole sensor calibration and validation

HPC covers the very high pressure ranges found in today and tomorrow’s oil & gas downhole applications. It is rugged and reliable, very well suited to use in remote locations and difficult environments where downhole transducers and tools are supported.

General calibration lab and shop use

HPC can serve as a versatile and easy to use calibration tool to cover a very wide range of hydraulic pressure with low uncertainty in all kinds of calibration facilities.

Analog gauge calibration in a calibration lab or manufacturing environment

HPC can execute large pressure changes quickly and make small pressure changes very precisely in just a few seconds. This makes analogue gauge calibration much easier and faster than with a deadweight tester, manual pressure generators or other controllers that lack this capability.

Pressure control component in an automated piston gauge system

HPC’s reliability, speed and ability to make very small changes in volume predictably by moving its intensifier piston make it the perfect solution for hydraulic control in an automated piston gauge system. HPC’s remote command set includes function necessary to support integration into an automated piston gauge system. Contact Minerva for additional information.

Read more about the MNR-800-HPC400 at the special website page with extra material like a video, an extensive user manual, an article about remote communication and download the brochure for more information.