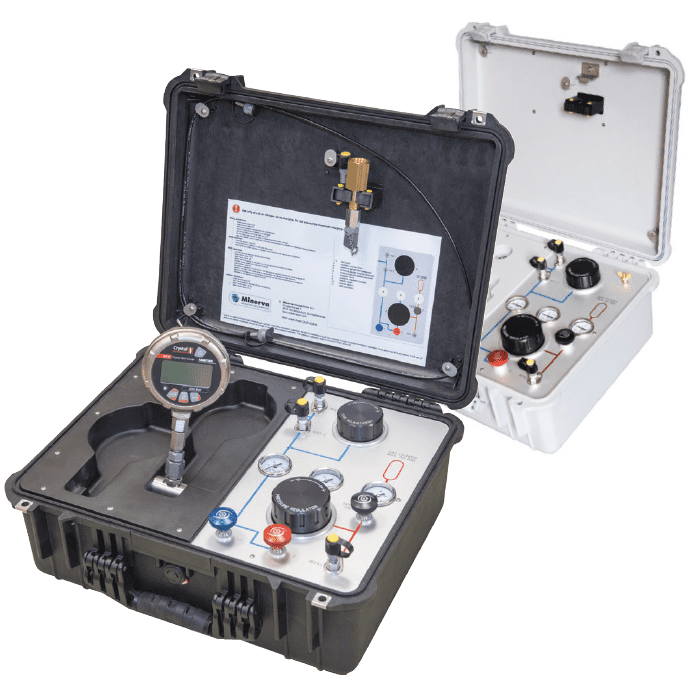

This case offers improved efficiency to quickly and safely perform clean, high pressure calibrations at your own location.

- Supports pressure ranges with full scale from 20 MPa down to 0.7 MPa in a single system

- Simple, compact and easy to operate

- Built-in refillable 28 MPa storage tanks for pressure supply

- Precise test pressure control using a pressure balanced volume controller

- Protected against overpressure

- Three analogue pressure gauges for monitoring pressure in storage system, regulated supply pressure and pressure at test ports

- Two test ports

- 316 SS high pressure tubing and fittings

- Additional option: ATEX certified version available for use in potentially explosive atmospheres.

Watch this explanation video

[et_pb_section admin_label="section"]

[et_pb_row admin_label="row"]

[et_pb_column type="4_4"][et_pb_text admin_label="Text"]

OPERATION

The built-in high pressure gas storage system is filled through the appropriate connection. Three separate monitor gauges are mounted to indicate storage system pressure, regulated pressure and pressure at test ports. The maximum test pressure is set using the supply regulator. The test pressure at the two test connections is precisely controlled by two fine metering needle valves and the pressure balanced volume adjuster.

The installed Crystal/Ametek digital pressure gauge displays the test pressure. Externally generated pressures can also be measured via the test connections. The instrument is supplied with quick-connect test and filling hose, a 1⁄4" NPT male adaptor for the test connection and filling and a refill connector.

IEC/ATEX certified IS version

Are you using the High Pressure Case in situations that require an IS calibrator? Then choose the IEC/ATEX certified case, especially designed and certified for controlling conditions in an explosive atmosphere.

[/et_pb_text][/et_pb_column]

[/et_pb_row]

[/et_pb_section]

TECHNICAL SPECIFICATIONS

| Pressure ranges | See Ametek XP2i or M1 series digital pressure gauges supported table page 3 |

| Pressure measurement specs | See Ametek XP2i or M1 series digital pressure gauges supported table page 3 |

| MNR 300 control range | 0 - 20 MPa gauge pressure |

| Gas storage system | 2 x 1 litre capacity, filling pressure limited to 28 MPa, tested to 45 MPa |

| Monitor gauges | 40 mm, analogue, all stainless steel: gas bottle pressure, regulated supply pressure, pressure at test port |

| Pressure regulator | Minerva Model 180 high pressure regulator, Range 0 - 25 MPa |

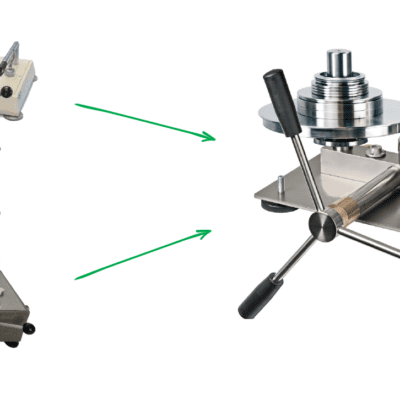

| Volume adjuster | Minerva Model 90, pressure balanced volume adjuster, displacement 11 cm3 max 67 turn, precise pressure setting to within 100 Pa, stainless steel interior |

| Needle valves | Fine control valve for test pressure inlet and exhaust |

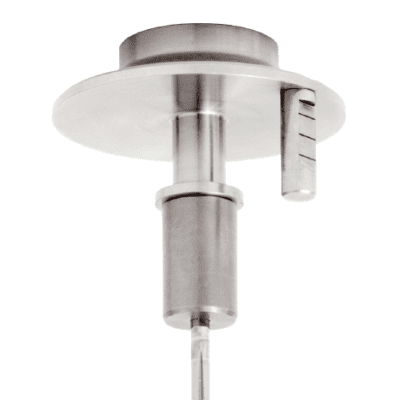

| Connections | Low volume Minimess 1215, quick connect couplings with internal check valve |

| Test / filling hose | Minimess 1215, length 2 meter, including 1⁄4" NPT male connector |

| Refill connection | For connection to nitrogen bottle, standard RU-3 |

| Quick lock system in lid | Quick lock system for storing test hose and test connector |

| Housing | Pelicase. Material: ultra high impact copolymer |

| Dimensions | 405 x 295 x 255 mm (L x W x H) |

| Weight | Approx. 19 kg |

| Certification | Pressure Equipment Directive (PED), Transportable Pressure Equipment Directive (TPED), CE conformity declaration |

| ATEX zone | II 3G Ex ic IIB T6 Gc (-10°C ≤ Ta ≤ +50°C) |

| Accessories included | 2 meter test / filling hose, 1⁄4" NPT male test adaptor, RU-3 refill connection |

| Documentation included | Manual, PED conformity declaration, TPED conformity declaration, CE declaration |

| Ordering code | MNR-300-CAXP2 |

| Ordering code ATEX version | MNR-300-CAXP2-ex |

MODEL NAME |

DESCRIPTION |

| MNR 300 - CAXP2 | Autonomous high pressure supply and adjustment system for Crystal/Ametek XP2i and M1 serie Digital Pressure Gauges |

| MNR-300-CAXP2-ex | ATEX version |

Product brochures

Brochure Minerva Portable High Pressure Case for Crystal MNR300 CAXP2 / XP2i ex

Brochures for regular, non-ATEX versions are available in:

- Brochure Minerva Portable High Pressure Case - Crystal MNR300 CAXP2 (German)

- Brochure Minerva Portable High Pressure Case - Crystal MNR300 CAXP2 (Spanish)

- Brochure Minerva Portable High Pressure Case - Crystal MNR300 CAXP2 (French)

- Brochure Minerva Portable High Pressure Case - Crystal MNR300 CAXP2 (Italian)

Demonstration video

Request a quote - Shop